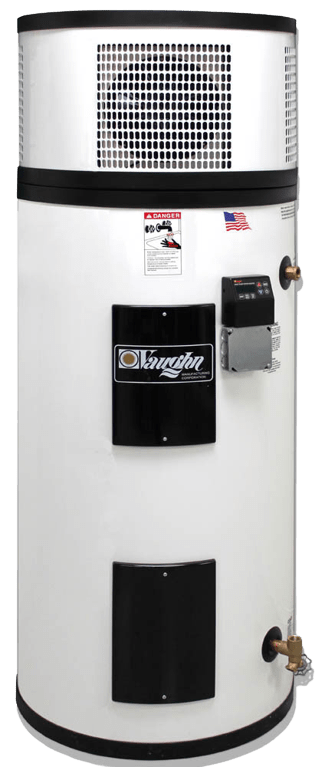

Commercial Water Heaters

Vaughn Commercial Water Heater's robust design combined with high efficiency are well suited for the demands of any commercial hot water application! Choosing Vaughn means plenty of clean hot water - a reliable system from a brand you can trust. Whether it is a corporate building, a hotel, a school or an apartment/condominium complex, Vaughn Commercial Water Heaters deliver comfort and convenience every time you turn on the faucet. Our Water Heaters and Energy Efficient Electronic controllers are both equipped with the latest energy-saving features and ANSI-approved safety technology. All products are warrantied and are available through our extensive network of dealers located throughout the U.S. and Canada.