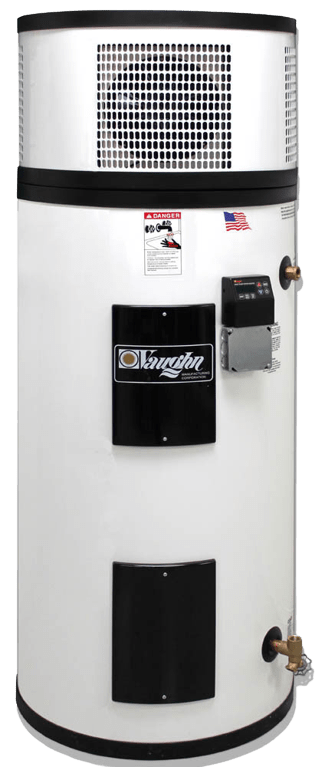

Residential Heat Pump Water Heaters

Vaughn's heat pump water heaters, also known as hybrid water heaters, employ the same process as a refrigerator, but in reverse. A fan at the top of the heat pump draws in air across a series of tubes called an evaporator. The evaporator acts like a dehumidifier, blowing cooler, dryer air back into the space. The heat from the ambient air at the water heater's location is transferred and pumped through a compressor to increase pressure and temperature. Because a heat pump runs lower-voltage fans and compressors, it may use up to 33% less electricity than a traditional electric water heater.