HydraStone Equals Cost Savings

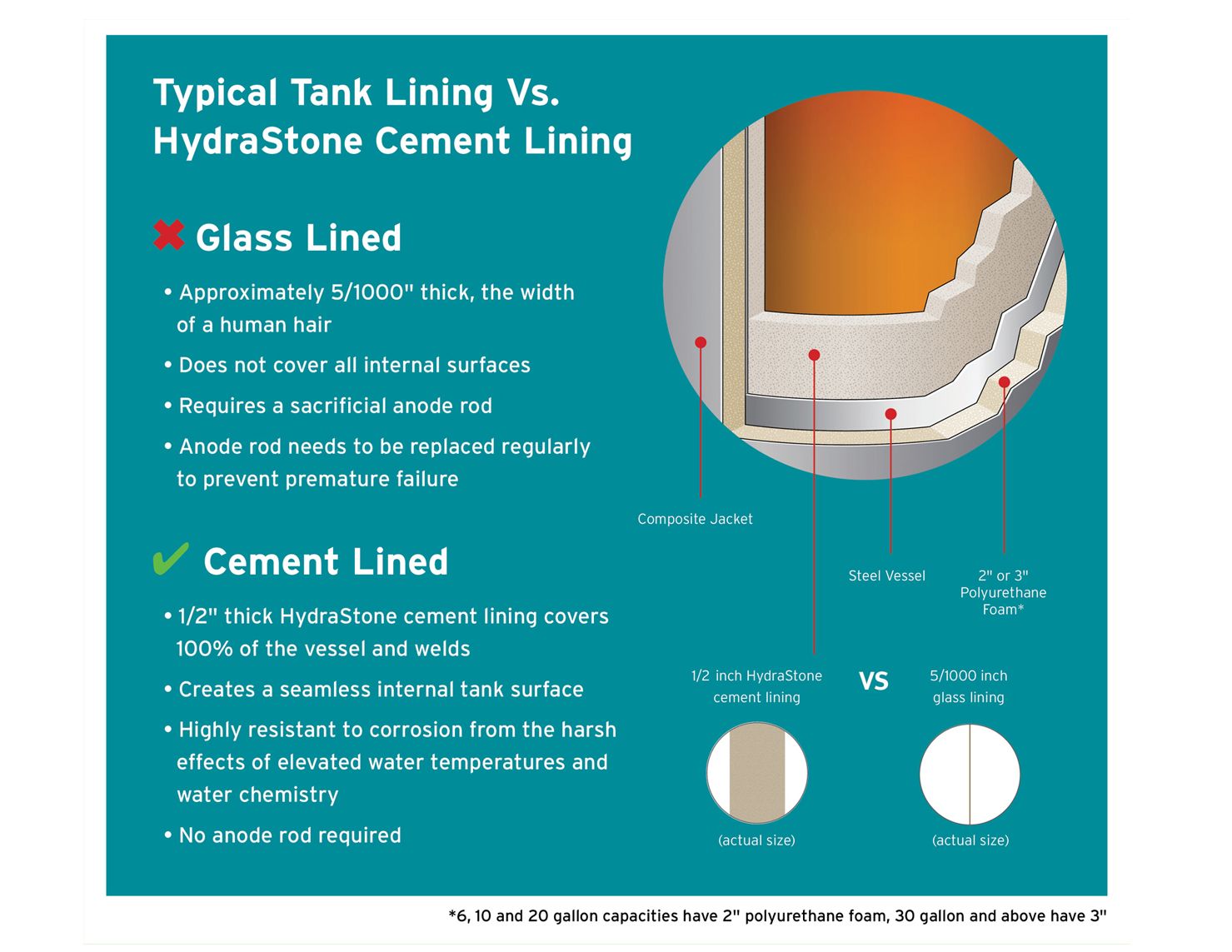

Using HydraStone cement lining in a water tank significantly reduces a customer’s total cost of ownership (TCO) by providing longer life and maintenance-free benefits. Additional savings can be recognized in the form of reduced operating expenses by eliminating the periodic inspection and replacement costs associated with maintaining a sacrificial anode typical in glass-lined tanks.

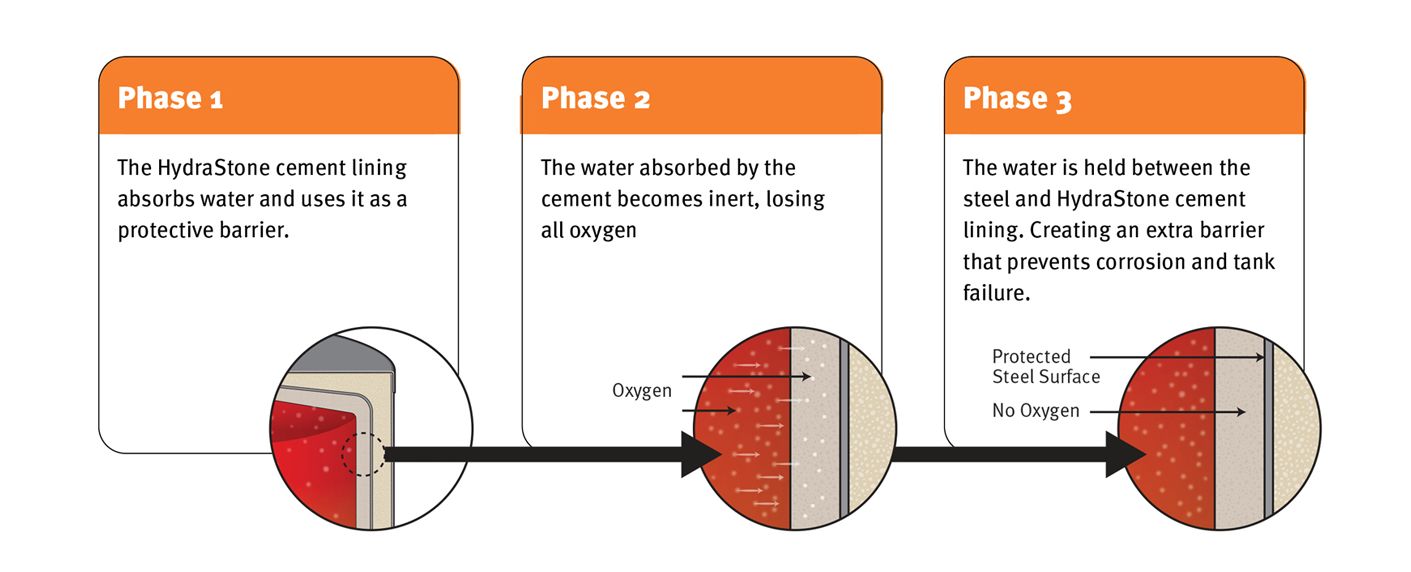

How does HydraStone Work?

HydraStone cement is specifically formulated to withstand the harsh effects of elevated water temperatures and a wide range of water chemistries. As water fills a cement-lined tank, it is absorbed into the tank lining. This action causes the absorbed water to give up its oxygen, creating an inert layer between the steel tank and the corrosive effects of water. In addition, unlike glass linings, the HydraStone cement lining has the same thermal coefficient of expansion and contraction as the steel tank. This ensures the liner will not de-bond from the tank surface during normal operation, maintaining its superior coverage.

Other Key Features of HydraStone

- HydraStone cement lining will typically last decades.

- HydraStone cement lining meets the requirements of NSF-61 for strength and potability.

- HydraStone cement lining can be repaired easily, or the tank can be re-lined on site, provided a manway is installed.

- HydraStone cement lined tanks offer significant longevity, trouble-free operation and a lower lifetime cost

How is HydraStone Applied?

The Nudyne Group (Ace, Hubbell, Reco, and Vaughn) specializes in the use and application of HydraStone cement in water tanks. Two methods of application are utilized at The Nudyne Group: hand-troweling and centrifugal spinning. Both methods provide the same durable, trouble-free lining, but centrifugal spinning is preferred as a less labor-intensive method.

Centrifugal spinning is generally used for tanks with a capacity of 500 gallons or less and is the only method used if there is no manway. During tank assembly, the top and bottom heads are troweled with HydraStone on the inside surfaces before they are welded to the tank shell. Once the tank construction is complete, the tank is mounted horizontally in a large lathe-style machine. A precise quantity of HydraStone cement slurry is introduced into the main opening, all other openings are temporarily sealed. Our cement slurry is specially formulated with specific properties beneficial to the spinning process. After the main opening is sealed, the tank is spun at an RPM and length of time specific to the size of the tank. This spreads the HydraStone cement slurry evenly throughout the interior shell of the tank and ensures that no air bubbles get trapped between the steel and cement. Any excess water is also forced to the surface of the cement and results in a smooth, homogenous, and durable lining.

Where centrifugal spinning is not practical, hand-troweling is the chosen method. When the amount of surface area requires it, a wire mesh or an array of metal pins is welded to the interior of the tank shell and heads. These will aid in creating a mechanical mounting system to which the HydraStone cement can attach and adhere. Once the tank is fully assembled, the required thickness of properly mixed HydraStone Cement is applied and smoothed using common masonry tools. For both methods, the HydraStone cement lining is applied to a 1/2" minimum thickness on all interior steel surfaces.

Better Water Quality Equals Longer Tank/Component Life

Ensuring proper water treatment and conditions for a water tank is essential for routine maintenance, promoting longevity for both the tank and its connected system components. It’s imperative that any water treatment program be overseen by a certified water treatment specialist.

Water tanks are especially susceptible to issues like scale formation and when exposed to feedwater containing high amounts of dissolved minerals. Among these, scale formation is the most common issue associated with water tanks, often occurring on the highest temperature surfaces, including tank walls, heating elements, heat exchangers, thermocouple probe shells, and other features. Excess and unchecked scale buildup within the water tank can lead to reduced capacity as it accumulates on surfaces and at the bottom of the tank.

Additionally, certain types of water quality issues can contribute to chemically induced corrosion of a heat exchanger, heating elements, or other ferrous components inside the tank. Various types of chemically induced metal corrosion may occur, including general or pitting corrosion. General and pitting corrosion manifests as a uniform attack on the tank, eventually leading to material thinning and failure.

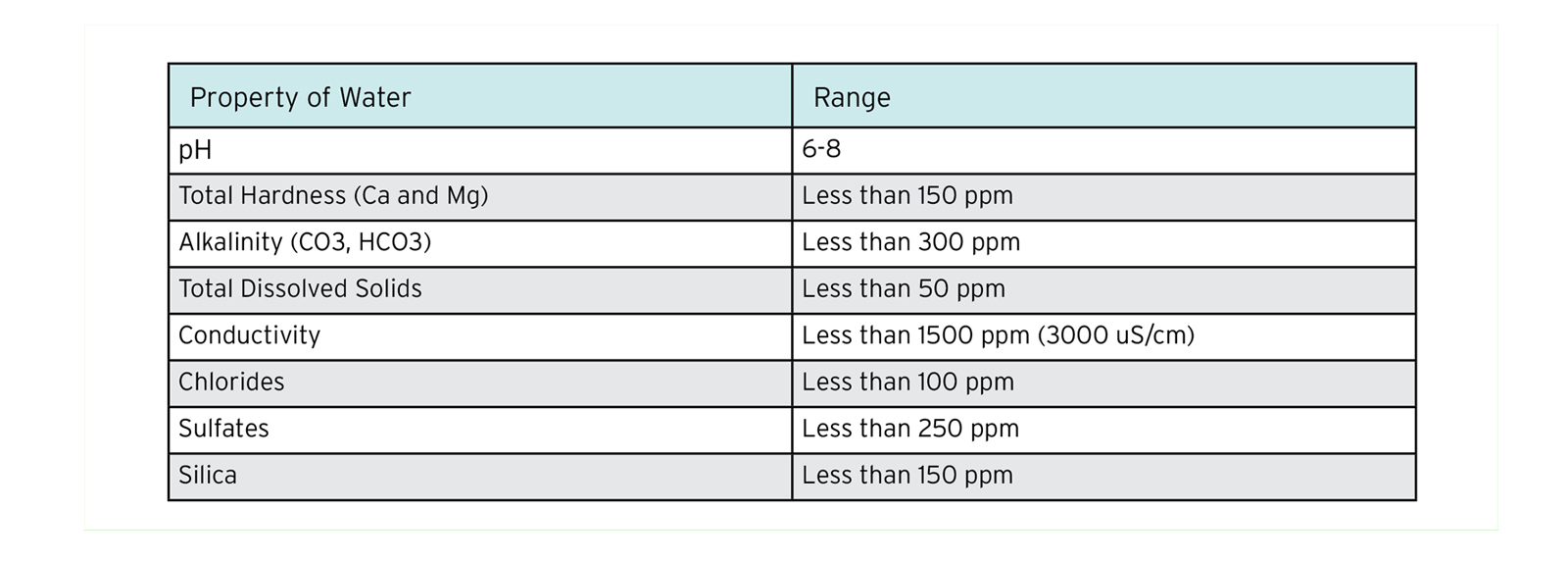

Below is a list of water properties and the recommended ranges for use in HydraStone™ cement lined water tanks to control corrosion and scale.

HydraStone™ Care

Proper care and maintenance of a HydraStone cement lining will ensure tank longevity and the best water quality. This includes regular inspections, appropriate cleaning/flushing, and timely repairs. Always follow safety precautions and manufacturer guidelines for the best results.

General Care

Annual Routine Inspections: Conduct regular inspections to identify the need for cleaning and any signs of wear or damage.

Cleanliness: Keep the tank clean to prevent microbial growth and physical damage from excess scale buildup.

Chemical Compatibility: Although cleaning agents are not necessary for a cement lined tank if you choose to use such agents ensure all cleaning agents and treatments are compatible with potable water standards.

FAQs

Will softened water negatively affect a HydraStone™ cement lined water tank?

Softened water will not affect the longevity or operation of a HydraStone cement lined water tank. A water softener is typically installed when a potable water system has hard water that is very high in dissolved minerals such as magnesium and/or calcium. Contrary to a glass-lined water tank, where water softener salt ions can corrode the anode rod and exposed steel surfaces, leading to leaks within a few years, a HydraStone cement-lined tank does not require a sacrificial anode and is unaffected by softened water.

What is the maximum temperature for a HydraStone cement lined water tank?

The HydraStone cement lined tank is suitable for storing water up to 210°F. However, there are numerous safety concerns that one must consider when storing water at elevated temperatures. Please consult Vaughn for questions regarding best practice.

Can a HydraStone Cement lined tank be repaired in the field?

Yes, if the tank is equipped with a manway, it is possible to repair a HydraStone cement lined tank in the field. In the event the cement lining is compromised, it is easily repaired in the field by maintenance personnel (no specialized training required) using readily available materials. See HydraStone repair procedure.

Why is a HydraStone cement lining a better choice than a stainless steel tank?

In almost all cases, a HydraStone cement lined steel tank is a more robust tank compared to stainless steel. A stainless-steel tank may be susceptible to SCC (Stress Corrosion Cracking) caused by chlorides, bromides, iodides, and fluorides in the water – unless it has been properly heat-treated or passivated. The combination of residual stresses from welding, roll forming and stamping, and the cyclic stresses from operating in a hot water system are sources of tensile stress. When tensile stress is above a certain threshold, the tank is more susceptible to stress corrosion cracking. HydraStone cement lined steel tanks are not susceptible to this condition, and therefore are more resistant to corrosion.

How do I prepare my HydraStone™ cement-lined tank for long term storage?

The tank must be stored in the orientation of intended use (vertical or horizontal). Cap and seal all openings, tank tappings, and/or flanges. Provide the necessary protection to ensure the tank and all accessories are protected from physical contact that could result in damage. Shrink wrapping or other suitable protective plastic may be applied to the exterior. Desiccant material should be inserted into the electric control panel and heating element terminal house (if applicable). Prolonged storage will require periodic inspection of desiccant. Start up and installation guidelines must be followed, with particular attention to testing the electric heating element. The recommended ambient air temperature range is between 50°F and 105°F and not exceeding 65% relative humidity. Under no conditions should the tank be subject to freezing temperatures. The tank is intended to be stored indoors, protected from the elements.

Why do I have a slight odor in my hot water or a ‘silky feel’ sensation on my skin?

On initial start-up the wet curing process in most installations occurs without affecting the water and is not noticeable to the user. However, due to several factors there may be instances where the user can sense that there is a change in the water, as mentioned above typically a “silky feel” sensation is noted and possibly a slight odor. As the wet curing process continues any possible change in the water will diminish and the water returns to normal upon full curing. The wet curing process is typically complete within 14 days of service. In applications with higher usage, the curing process is faster, and in applications with relatively low usage the process takes longer. However, in almost every instance the process is complete after 14 days of normal operation. If the user is experiencing a moderate change in their water, the water heater can be serviced to help minimize the change. A technician can fully drain and flush the tank and then add a water softener. This process helps remove excess calcium and reduce the pH level of the water, thus minimizing the noticeable change in water. Allow the tank to complete the wet cure process over the next 14 days.